Our story is a whole century’s worth of dreams and struggles of a country growing through a hard-won Independence; of giving back to the society more than what we take from it.

Our story is the manifestation of the hopes and aspirations of our people.

We make textiles, and we make homes. We fuse the offline and the online. We challenge what’s possible by fashioning newer possibilities. We are Arvind. And this is our story.

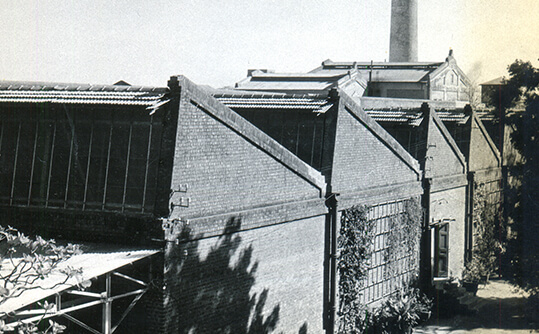

1897

1897At a time when there was hardly any manufacturing activity in India, Lalbhai Dalpatbhai set up his first mill, the Saraspur Manufacturing Company.

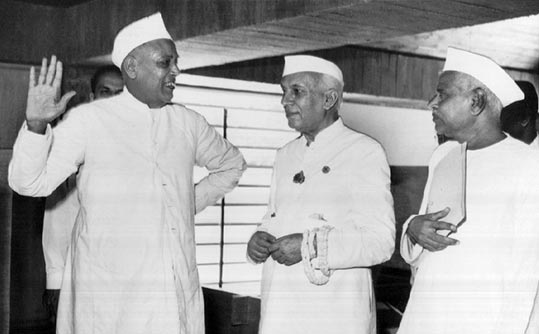

1931

1931In response to Mahatma Gandhi’s call for Swadeshi during the struggle for Indian Independence, the Lalbhai family founded Arvind Mills, creating a capacity to compete with the world’s finest textile mills.

1935-38

1935-38Arvind's butta voiles were being exported to Switzerland and United Kingdom (UK), thereby realizing the full potential of the spirit behind Swadeshi.

1952

1952After two decades of success in the textile industry, Kasturbhai Lalbhai set up India’s first dye and chemical plant, under the aegis of Atul Products Ltd, in order to reduce the nation’s dependence on imported dyes, and chemicals.

1973

1973The Narottam Lalbhai Research Centre was established, to further the Company’s technical capabilities. The Centre was home to many path-breaking innovations in the years following its establishment.

1980

1980Flying Machine, India’s first denim apparel brand, was launched to meet the aspirations of the emerging youth segment.

1985

1985Renovision, a new strategic plan for the Company, was introduced. It was to put Arvind and India on the global map of denim manufacturing. Just as India, a protected economy, was opening up to the world, Arvind had firmly shifted its focus on domestic to international markets.

1986

1986Arvind’s – and India’s – first denim manufacturing plant was commissioned at Naroda Road, Ahmedabad. Arvind was soon to emerge as a global leader in denim production. By the end of 1987, Arvind also started manufacturing high-value cotton shirting.

1993

1993Through tie-ups with V.F. Corporation (USA) and Cluett Peabody & Co. USA, for manufacturing and marketing, Arvind was able to offer high quality global apparel brands like Lee Jeans and Arrow Shirts to the Indian market.

1995

1995To formalize its Corporate Social Responsibility (CSR) efforts, Arvind launched the ‘Strategic Help Alliance for Relief to Distressed Areas’ (SHARDA) Trust.

1996

1996As a part of its CSR efforts, a unique Private-People-Public partnership was launched with SHARDA Trust, the Ahmedabad Municipal Corporation and residents of the Sanjay Nagar slum coming together to transform this into a model of urban planning and low-cost housing.

1996

1996The foundation was laid for one of India’s most modern textile manufacturing units at Santej, near Ahmedabad. Spread over 450 acres and an investment over Rs. 1,000 crores, the plant was designed to produce high-value cotton shirting, bottoms and knitted fabric for international markets.

1998

1998Santej shirting facility, with a capacity of 34 million metres, was commissioned this year. Over the next 20 years, Santej became globally recognized as the benchmark for sustainable practices in the textile industry.

2008

2008To accurately reflect the multi-faceted nature of the organization, the name of the Company was changed to Arvind Ltd. from Arvind Mills Ltd.

2010

2010The Arvind Store was set up to house the best brands of Arvind under one roof. The store offers not only the entire range of the Company’s fabrics and apparel but also the services of Studio Arvind, the bespoke tailoring unit. There are currently over 180 Arvind Stores across India.

2011

2011Beginning 2011, Arvind has brought in some of the biggest global fashion brands like Calvin Klein and Tommy Hilfiger to India

2011

2011First Better Cotton Initiative (BCI) bale produced from India, from the Arvind farm project in Akola. BCI seeks to grow cotton responsibly by controlled application of water & use of approved fertilizers; thereby dramatically reducing the footprint of cotton farming. Arvind is one of the largest implementation partners of BCI in India.

2014

2014Arvind scored a major win. Arvind Envisol, a subsidiary of the Company, which provides waste water treatment solutions, got a global patent for its Polymeric Film Evaporation Technology (PFET). This revolutionary technology saves 80% energy cost for Envisol’s Zero Liquid Discharge water treatment system.

2014

2014A brand created to fulfil everyone’s individualities. Creyate offers fine, bespoke menswear with a degree of customisation never seen before.

2015

2015Arvind partnered with USA-headquartered Invista, the owner of the Lycra fibre brand, to manufacture stretch denim fabric in India.

2015

2015With the birth of Khadi Denim, the legacy of Swadeshi, which had inspired the founding of Arvind, came full circle. Each single yard of Khadi Denim is spun, dyed and woven by artisans carrying on centuries-old handloom traditions. It is perhaps the most sustainable denim fabric ever made: no chemicals, no electricity, no high technology, no use of depletable resources.

2015

2015Denim went smart as Arvind collaborated with the world’s largest internet giant and the world’s most renowned denim brand to launch wearable denim technology and smart denim jackets. Arvind also launched a 4-in-1 smart shirt in collaboration with Arrow.

2015

2015Arvind launched Project Asmita to provide for sanitation needs in rural areas. It brought together highly skilled professionals and technicians and tasked them with the challenge of coming up with strategies to raise the standard of sanitation practices in rural India. The result was a low-cost toilet that is a fusion of innovative modern and traditional materials that could be readied and installed in just a day.

2016

2016Arvind launched Nnnow.com, a one-stop shopping destination for trendsetters across the country.

2017

2017Building on an 86 year legacy of craftsmanship, innovation and fashion leadership, Arvind launches its own Ready-To-Wear brand.

2017

2017In November 2017, Arvind Ltd announces the proposed demerger and public listing of its branded apparel (Arvind Fashions) and Engineering (Anup Engineering) businesses.